Home

List of Blogs

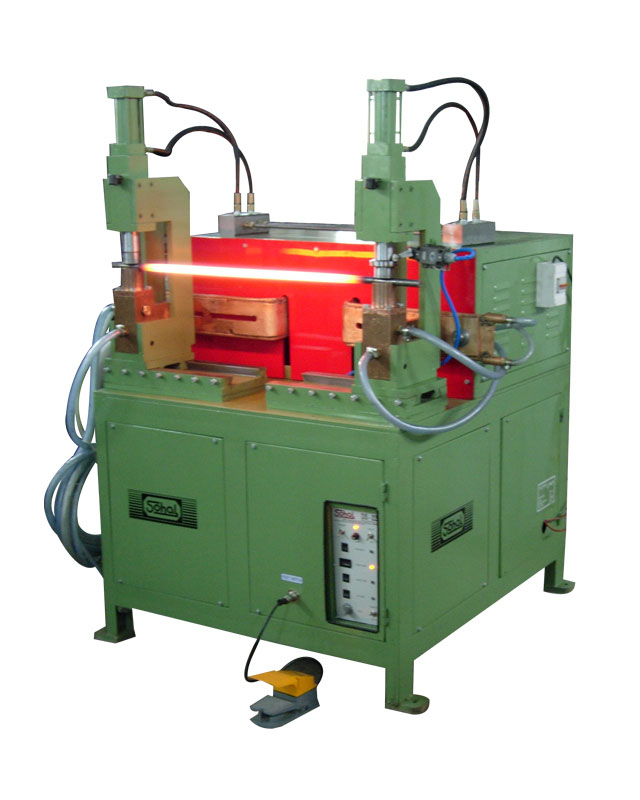

Resistance heating for U-bolt manufacturing plant

Resistance heating for U-bolt Machine

factory was in delhi iam purachase new resistance heating for u-bolt machine so machine is very fast production save money and save my time machine was good working so i recommendation purachase this machine contact sohal Electric works

Get Started Contact UsResistance heating for U - bolt manufacturing plant

In the realm of industrial manufacturing, efficiency is key. Every process, every machine, every innovation is geared towards streamlining production, reducing costs, and enhancing quality. In this pursuit, heating machines play a pivotal role, especially in industries reliant on precise temperature control for their processes. For making U-bolt the iron rod should bent to make flawless U shape. To make flawless good quality U shape the iron rod should be heated first before bending. Here comes the role of electric resistance heating machine also known as U-bolt heating machine. The machine consists of a control circuit and step down transformer to match right heating of iron rod.

Our Services

SCR controlled machines

SCR controlled machines have following features.

• Synchronized Heating Timer

• Fast pneumatic clamping

• Heat Delay Adjustable

• Power Line Synchronized Thyristor Control Step less Power setting

• Heating Time from 1 to 200 seconds

U-Bolt Heating Machine

The U-Bolt Heating Machine is a versatile and indispensable tool in various industries such as manufacturing, construction, and engineering. It is primarily utilized for heating and bending metal rods or bars to specific angles or shapes. The machine's design allows for precise control over the heating process, ensuring uniform heating and consistent results.

At its core, the U-Bolt Heating Machine operates on the principle

At its core, the U-Bolt Heating Machine operates on the principle of induction heating. This method involves generating heat within the metal object itself by inducing electrical currents through it. The machine consists of an induction coil that wraps around the metal rod or bar to be heated. When an alternating current passes through this coil, it creates a rapidly alternating magnetic field. As the metal object is placed within this field, eddy currents are induced within it, causing it to heat up due to resistance.